The global energy consumption is estimated to be 580 million terajoules per year, with about two-thirds accounting for electricity consumption alone. Global electricity generation is expected to reach nearly 45 trillion kilowatt-hours (kWh) by 2050. The demand for energy is ever-increasing. The pandemic put a brief pause on this growing demand, with a fall of 1% in 2020, but it came back up quickly and is expected to grow by 4% this year. The usual suspects – population, economic development, and advances in technology – are the key drivers for this growth in demand.

How is this energy produced?

Today, much of the energy consumed is sourced from fossil fuels such as oil, coal, and natural gas. High energy-consuming countries such as China, India, and the US are still reliant on fossil fuels, with 71% (China), 59% (India), and 61% (USA) of energy coming from these sources. However, fossil fuels are rapidly depleting and also hampering climate goals.

Governments and organizations worldwide have recognized this and are equally and heavily invested in identifying new sources of energy - sources that are cleaner for the environment and the planet.

Energy generation from renewable sources such as wind, sun, and water is set to increase over the next few years. Renewable energy sources accounted for close to 30% of the global electricity generation in 2020. By 2050, renewable sources are expected to contribute to 80 to 90% of global energy consumption.

There are, of course, several challenges to the widespread adoption of renewable energy sources - the prohibitive cost of installation, their distributed nature, the need for new transmission infrastructure, unpredictability due to weather, political influences, and market conditions.

Given this juxtaposition of factors, governments and energy bodies globally urgently need a solution to optimize energy production, distribution, and consumption from multiple sources.

Enter Smart Grid: The way forward for smart energy management

This is where Smart Grid comes in. A Smart Grid is an electrical grid with automation, communication, and technology that help monitor the flow of power from its point of generation to the point of consumption, thereby controlling or curtailing the load to match the generation of power in real-time.

Primarily leveraging IoT technologies, a Smart Grid helps to proactively detect and respond to consumer needs. It enables analysis, and communication of information to enhance efficiency and transparency across the supply chain, optimize energy consumption, and improve the reliability of the supply.

Smart Grids help to make transmission efficient, identify and resolve outages, predict the peaks and troughs in demand to optimize utilization and reduce wastage, improve operational costs for utility companies, and enable smoother integration with renewable energy systems.

In this way, Smart Grids provide the advantage of connected distributed energy resource assets, including renewable energy sources.

Efficient transformer monitoring at the core of the Smart Grid

Transformer monitoring is a key element in the move toward Smart Grids. It provides power producers the transparency to make critical decisions on power production and optimize power consumption. Transformer monitoring also enables demand analysis - what is being consumed by every household or industry or commercial establishment, in which areas is the consumption higher, and what are the peak periods of demand.

Let’s take a look into the types of transformers that utility companies typically deal with:

Electrical transformers constitute the largest share of investments in any utility system. Hence, replacing the electrical transformers frequently for better efficiency is an expensive proposition for most industries. The average lifespan of a transformer is 30-40 years. However, the costs of transformer failure are high, up to $15 million. So, it’s critical to ensure that the best monitoring and control system to maintain the transformer is in place.

Globally, transformer fleets are operated beyond their designed life and with higher average loads resulting in catastrophic failures.

Causes of transformer failure

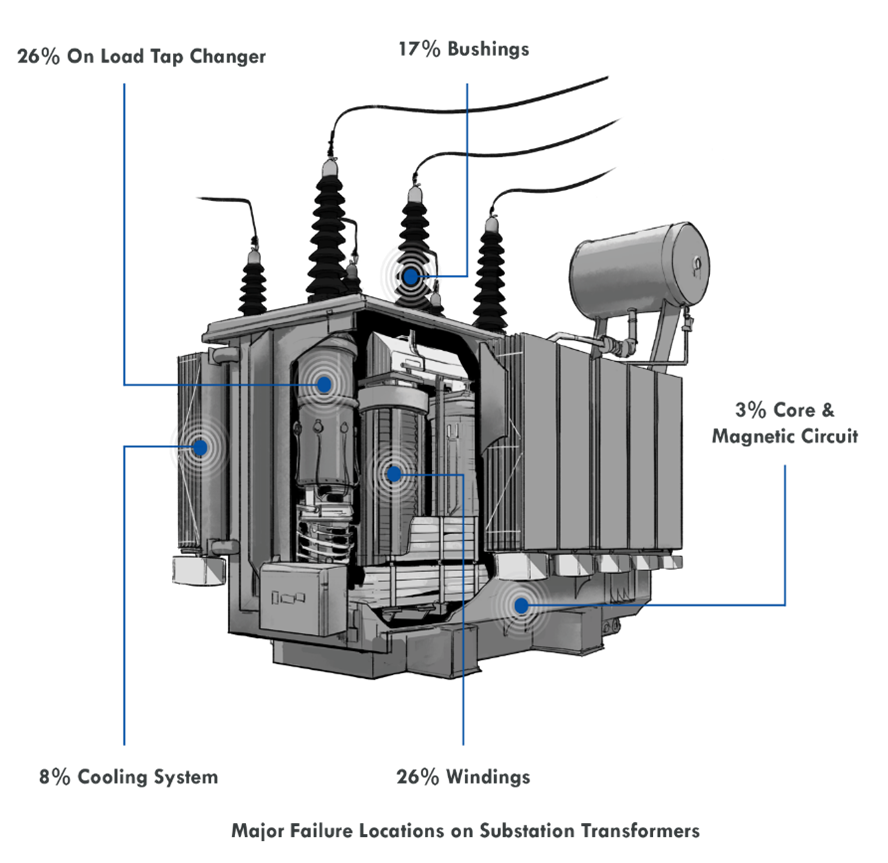

There are several reasons why a transformer fails. Evaluating aspects such as the technical condition of the transformer, based on an analysis of its make and model, features, number of years of usage, location, and other factors can help determine the risk. Figure 1 gives an overview of the key technical causes of transformer failure.

When it takes 7 days or more for investigation, remedial work, or replacement, it is considered a major failure on a transformer. To mitigate the risk of failure, it’s important to determine the probability as well as the consequences of failure. Unexpected failures can also have significant cost impacts.

How transformer monitoring systems help to optimize power distribution and usage

As renewable energy sources are increasingly providing power across the globe, the distribution systems are also changing. Hence the greater role of transformer monitoring.

Transformer monitoring can be done in two ways – offline and online. Offline monitoring allows technicians to perform condition testing without any constraints. However, the major drawback is that the transformer has to be taken off the grid, which is both cumbersome and expensive for the power company. Online monitoring leverages technologies that don’t require taking the transformer offline. In addition, the offline monitoring system can only provide a historical overview of the health of the transformer, unlike an online monitoring system, which can provide updates in real-time. The former can lead to the aging and deterioration of insulation which causes the most catastrophic transformer faults. With an online system, real-time interventions can help predict failures and plan for such events.

For producers of power from renewable sources such as wind and solar energy which are unpredictable, the ability to predict transformer failure and proactively repair or replace parts, especially when the energy is not being produced, is invaluable.

Hence, with an online monitoring system, the standard offline diagnosis limitations can be easily mitigated. In a nutshell, an online monitoring system:

Powering into the future with Smart Grids

Given the prohibitive costs of replacing a transformer as well as the cost incurred in maintaining them to last an expected lifespan of 30-40 years, transformer maintenance is key to profitability for utility companies. However, costs are not the only aspect of transformer maintenance. With the increasing demand for energy resources, downtime or outages are not an option. The world’s reliance on fossil fuels will eventually reduce, and renewable energy sources will contribute significantly to energy production. As we move towards this scenario, optimum utilization of all the resources with minimal wastage is a priority for all concerned. Leveraging new-age technologies such as IoT, automation, and even AI or ML, to make the Smart Grid even smarter and for effective online monitoring of transformers is the way forward.

Purushottam Konar

Purushottam is the Global Head of Product and Solutions Engineering at Wipro. He has over 22 years of experience in design, development and deployment of enterprise solutions and products for large multifunctional organizations across different verticals. Purushottam has extensive experience in architecting & building products, platforms and solutions in the IoT and IIoT domains. He is currently responsible for the global product and solution engineering charter of Wipro’s IoT practice. He holds a Master’s degree in Computer Applications