Industry Overview

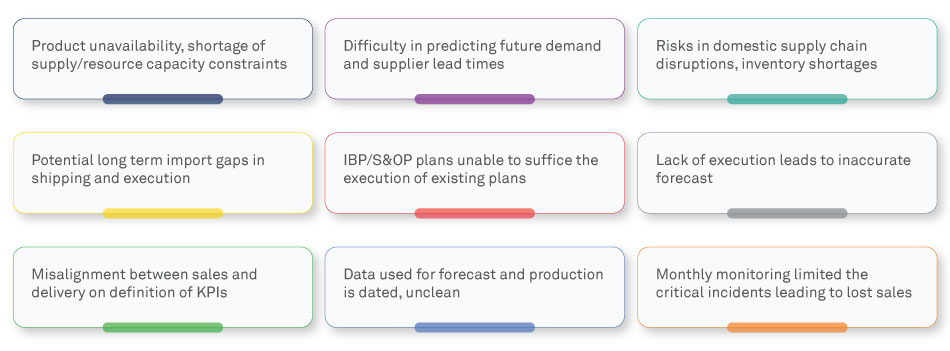

Global manufacturing organizations and their supply chains constantly face a time crunch to enable cross functional collaboration across their sales and operations execution function (S&OE). Teams often spend a lot of time trying to understand discrepancies that impede improved accuracy, revenue capture, high customer service levels, and reduced overall spending in their execution plans. Factories and warehouses continue to face a labor shortage, material and distribution delays, production constraints, and regulatory uncertainties. The COVID-19 pandemic is an example of how supply and demand shocks can convulse value chains. Other unprecedented situations like Brexit, trade wars, recession, weather changes, fluctuating oil prices also impacted organizations in multiple ways, including:

There is a reactive response to handling critical events along with the lack of an established framework to deal with the daily and weekly adjustments to maintain mid to long term plans. This has resulted in an overreaction to the most minor disruptions. Although organizations work hard to optimize their integrated business planning (IBP) or sales and operations planning (S&OP) functions, they do not examine their execution capabilities closely. As a result, the S&OP performance of several organizations is rudimentary and needs value benefit realization.

Critical events and fluctuations in demand, capacity and material shortages, inefficient collection mechanisms, and increased lead times from suppliers can instantly reveal the weak points in an organization’s value chain. The lack of a structured and systematic framework to manage these unexpected events leads to execution issues.

Some key questions that executives and their teams need to answer:

Why is it critical to integrate S&OP and S&OE to create a robust supply chain?

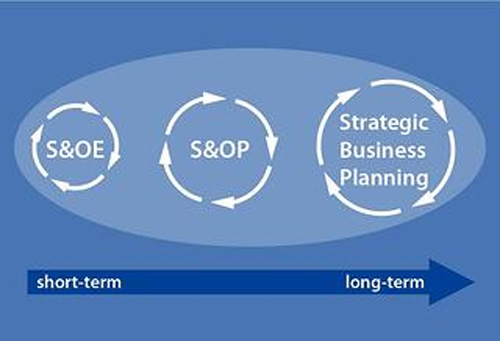

Manufacturers work hard to develop a long term plan to achieve business goals. S&OE horizon ranges from weekly to monthly planning and gives more visibility on daily activities. S&OP, on the other hand, addresses one to three-year planning. S&OE and S&OP complement each other to smoothen out the manufacturing planning process.

Key Findings

According to Gartner’s studies, the biggest challenge that manufacturing organizations face is to connect their IBP/S&OP to real time S&OE.

Gartner’s research found that nearly 31% of manufacturing organizations revealed a commitment to integrated planning and execution, where their long and midterm planning process combined with tactical execution through a single, connected platform accessed by users across the manufacturing and supply chain functions.

Gartner also suggests that organizations that follow an integrated S&OP and S&OE approach with ongoing daily S&OE reported benefits such as greater profitability, increased customer service levels, and reduced overall spending.

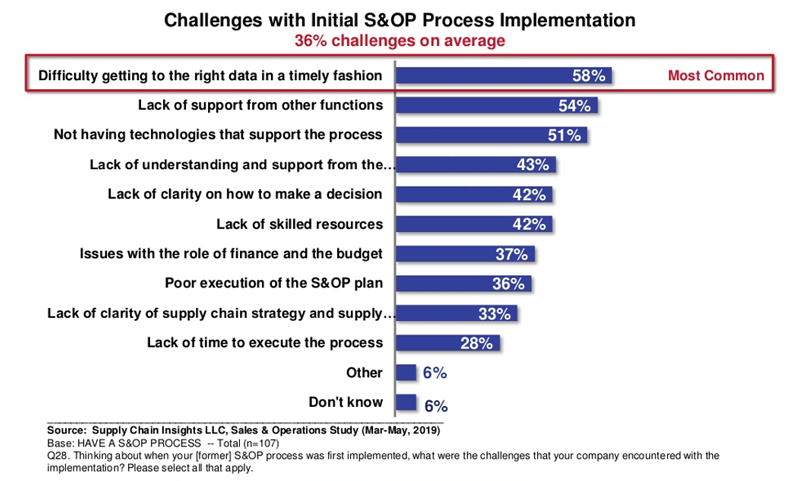

According to studies conducted by Supply Chain Insights LLC in 2019, some of the significant pitfalls included a lack of capabilities in executing S&OP schedules and plans. The figure on the right highlights the issues responsible for the challenges in the initial process implementation of S&OP, which is mainly due to a lack of extension available for S&OE. Some of the highlighted critical variables in red are due to lack of S&OE:

Single source of truth for S&OP and S&OE was missing, and a lack of data digitization across the value chain.

No clear definition of S&OP vs. S&OE, lack of critical KPIs/events classification, and ongoing management.

A good S&OE CoE (Center of Excellence) team was not available or set up, to act as an extended arm of the S&OP/IBP. Neither was an operations function available to provide ongoing support for execution actions.

Reactive strategies, longer time horizons, and no process readiness in place for S&OP teams to manage real time, short term execution of plans.

Difficulty in identifying and resolving predicted issues before they occurred. This was due to a lack of time and a lag in information sharing.

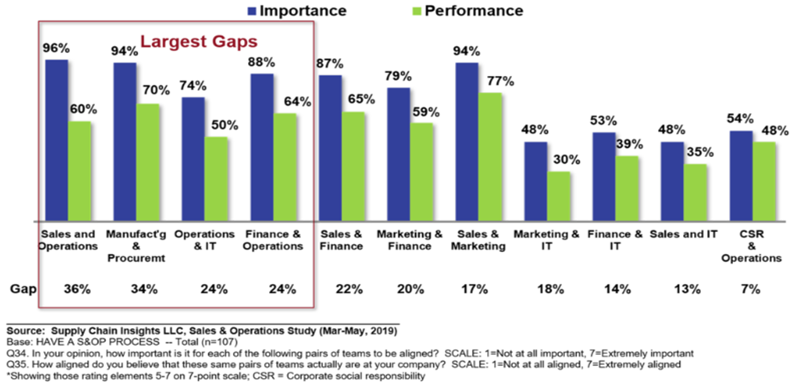

As per research by the Supply Chain Insights LLC group, some organizations that already have the necessary S&OP or IBP processes, tools, and platform setups continue to face widening alignment gaps among their functions w.r.t ‘importance of the processes’ vs. ‘performance of the processes’. A huge 36% gap is observed in S&OP ‘importance vs performance.'

The main reason for this gap is attributed to the challenges around the nonavailability of S&OE and the time frame of the monthly S&OP cycle, which leads to difficulty in capturing real time or short term execution events.

Operational and financial impacts of a failure to integrate S&OP and S&OE

The current challenges have a substantial impact on manufacturing supply chain operations and financial metrics:

S&OE is a critical extension to planning and operations

In these uncertain times, companies must become adept at managing risks to maintain a competitive advantage. It is important for companies to make predictions and take decisive action, and not wait it out in the short term. Implementing agile, digitally enabled planning as well as developing an execution framework that responds deftly to changing market conditions is needed to future proof your operations.

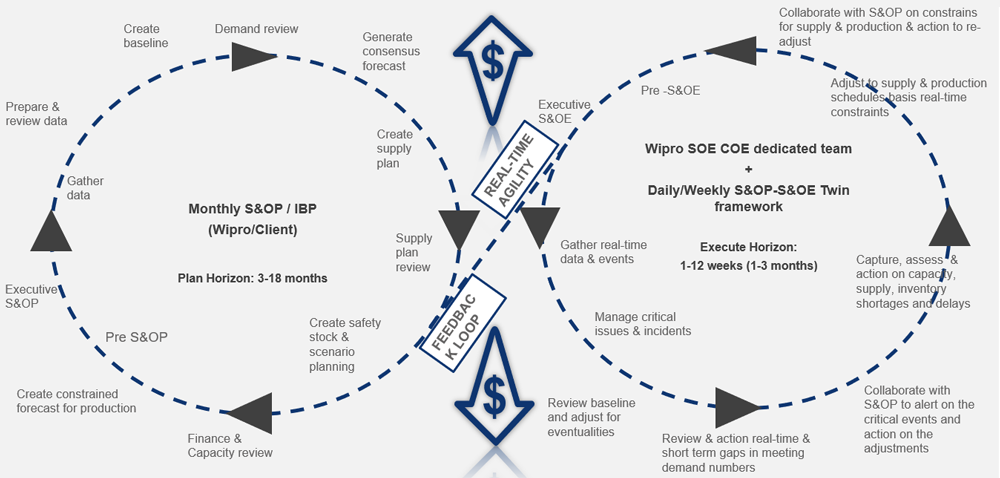

A structured, systematic, and defined decision making process to plan for eventualities and course corrections as an ‘S&OE’ will bridge the plan to execution gap. Organizations should manage the S&OP and S&OE separately, within their respective long or midterm/short term time frame. However, they should also keep them closely intact w.r.t extending data and visibility as a single source of truth, collaboration across cross functional stakeholders, and creating an advanced execution framework, such as a twin to mirror the S&OE process with the S&OP/IBP processes.

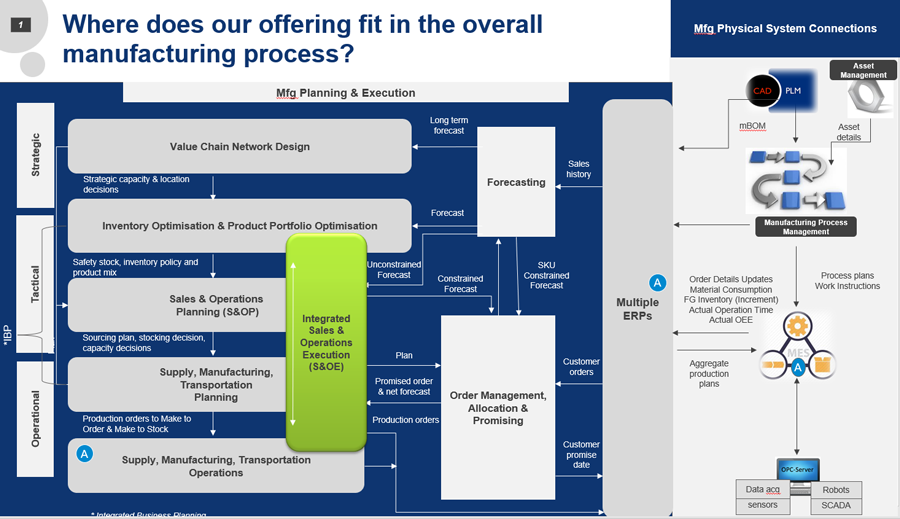

The figure below illustrates S&OE play across the overall manufacturing organizations’ value chain.

S&OE cuts across the tactical plan, execution plan, and operations to provide critical execution support across these three parts of the overall value chain. While S&OP/IBP helps in monthly response planning, S&OE assists in predictive planning and reliable execution.

Shortages, potential risks, inbound and outbound shipment delays, excess or redundant inventory, supplier lead time mismatches and the reported daily/weekly uncertainties, external causes creating short term disruptions in execution, real time production/supply/transportation/distribution gaps, and their root causes; the S&OE can handle all these. S&OE flags the disruptive variables, adjusts the short term schedules, alerts the operations teams on changes and constraints, and collaborates with the S&OP to help adjust their plans fortnightly, monthly or weekly.

S&OE can also help manage execution plans of the overall network, supply chain and distribution, factories, and equipment levels. S&OE teams perform root cause analysis, what-ifs on short term and constrained parameters, build strategies for execution disruptions, and ongoing real time incidents/events track/trace/monitor/report – all these are crucial for manufacturing organizations to manage the key benefits and outcomes delivery with S&OE mentioned below:

Create a robust supply chain to beat disruptions

Disruptions, uncertainties, and recessions create uneven recoveries, posing significant threats for organizations in meeting their bottom line. So, where should organizations begin and focus?

We have identified three key actions that organizations can take right now to mitigate disruption risks to their value chains. Performing these actions now will mean greater security to manage supply, rapid cost takeout, address lost sales, and optimize financial/ service levels/working capital/resiliency goals. The client can realize all these benefits within three months.

ACTION 1: Secure cash flow and improve working capital to manage business continuity.

In times of crisis, cash is of paramount importance. Short term vulnerabilities need swift action and business as usual implemented.

Start by setting two different teams to manage S&OP and S&OE processes and activities. Both teams should have different agendas, cadence, goals, KPIs, and action points. Have a dedicated S&OE Center of Excellence (COE) team to manage the frequent cadence, short term and even real time uncertainties, events, and incidents. Onboard S&OE teams and start the S&OE activities to manage disruptions and business continuity.

The S&OE teams can stabilize operations by providing a quick view of critical disruptions and execute actions needed to maintain inventory levels, alternative suppliers, pay terms acceleration for critical suppliers, and collections efficiency– all very important to maintain cash flows and optimize working capital.

ACTION 2: Re-evaluate or create a framework to accelerate the digitization of S&OE.

Making the right cost reduction decisions and bringing about transformations in digitization is the key to unlocking efficiencies.

Assess and evaluate the current process, tools, and platforms used by the planning teams, analyze gaps, extend the tools/platform, if capable, to perform S&OE.

Create an S&OE framework/workflow for the CoE to perform ongoing S&OE activities, extract meta data and critical KPIs/process metrics. Use AI/ML and deep dive advanced analytics for real time data capture, deep dive analytics on critical misses, alerting, and highlighting disruptions. A digital System of record (SOR) will help organizational interventions, create a repository of best practices of vast data sets, use real time single source of data to become smarter and more autonomous over time.

Setup an S&OE twin of S&OP processes and meetings, which can be weekly instead of monthly, to monitor, adjust, and action short-term execution gaps.

ACTION 3: Ensure that ongoing daily execution outcomes – not just monthly planning outcomes – are maintained as top priority.

Create S&OE focused metrics, clear KPI definitions between S&OP and S&OE, and delivered and managed outcomes daily to realize improvements. Having real time connectivity to shine light on the actionable short term and real time insights is the digital foundation of visibility. Create an S&OE command center and visual control towers across the network for visibility of critical events, incidents, disruptions, and actions, in addition to the S&OE CoE intelligence.

With targeted, structured, precise, and daily ongoing execution, it is easier to gain control of uncertain situations and overall spends. Aligning on a common execution strategy with the cross functional planning and execution teams will help in agility and long term resiliency in supply chain and operations. For this, it is equally important to generate an innovative and agile feedback loop for S&OP-S&OE collaboration on an ongoing basis.

Conclusion -- Weathering the STORM!

While it is impossible to know what the future will bring, we must plan for immediate focus – to address short term challenges and structure our approach to action the uncertainty that the future will bring in.

Businesses must predict and be proactive, using quick execution actions, rather than be reactive in weathering the storm. In a volatile environment of operations and complex supply chains, having a dedicated ongoing S&OE team managing supply chain resiliency and agility is essential to success. It will be the difference between leaders with predictive planning and proactive execution vs. laggards with only reactive planning.

About Wipro’s S&OE offering:

WIPRO’s THREE POINT SOLUTION AND STRATEGY ON S&OE:

The figure below illustrates Wipro’s S&OP-S&OE Digital Twin framework:

Is your organization struggling to enable collaboration across the sales and operations functions in order to create stronger execution?

Please reach out to the Wipro experts mentioned below for further details.

Anand Gejjalli Rashmi

AVP Practice Manager Practice

[Manufacturing] [Manufacturing]